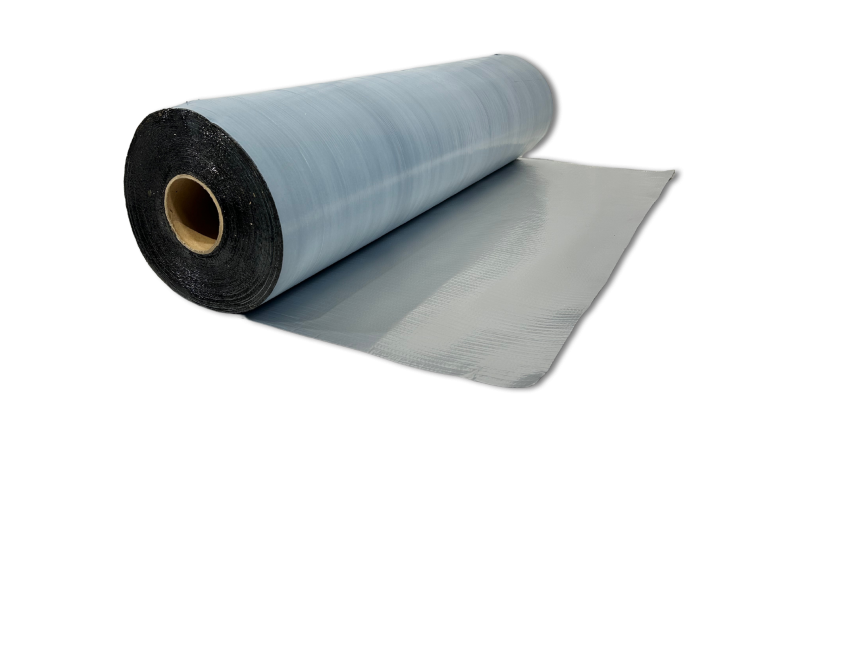

STRATAVAP

Vapour Barrier

StrataVap is a cold-applied, self-adhesive bituminous air and vapour barrier which is saturated and coated with high quality SBS (Styrene-Butadiene-Styrene) modified bitumen. It has an integrated aluminium foil layer, a glass fibre reinforcement and is finished on the underside with a removable siliconised film.

Advantages

- Cold-applied, self-adhesive application

- Ideal for flame-free installations

- Steam sealing technology

- Walkable and puncture proof

- Excellent tear strength resistance

- Forms an airtight layer

- Resistant to chemicals and aging

- Excellent low temperature flexibility at -25°C

Usage

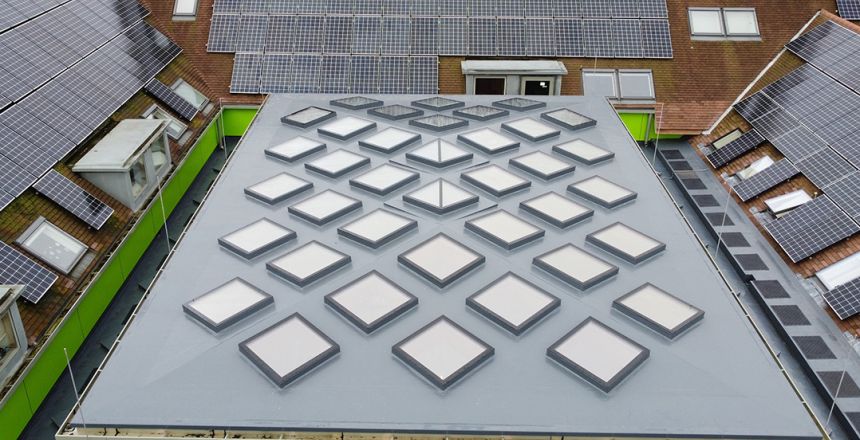

- Metal profiled or plywood decking

- Areas prone to increased temperatures and moisture levels (e.g.factories, swimming pools, gyms)

Product Details Back to top

Product Specification

Store in a cool, dry place in an upright position and protect from direct sunlight.

Technical Data

| PROPERTIES (test method) | DECLARED PERFORMANCE |

|---|---|

| Length | 30m |

| Width | 0.95cm |

| Weight per m² | 1.01 kg/m² |

| Tensile strength (EN 12311-1) | 500N/50mm (min)v |

| Water vapour permeability (EN 1931) | Sd: 1,500m |

| Flow resistance at elevated temperatures (EN 1110) | ≥+85°C |

| Flexibility at low temperatures (EN 1109) | -25°C |

| Dangerous substances | None |

| Visible defects (EN 1850-1) | None |

Applications Back to top

StrataVap should be installed in accordance with manufacturer recommendations and all relevant national standards and codes of practice, including BS 8217: 2005 – the code of practice for reinforced bitumen membranes for roofing.

The membrane should be unrolled, aligned and set into position alongside other rolls and profiled decking. Once aligned, one end of the siliconised film should be peeled back. The edge of the StrataVap membrane can then be pressed to the profiled decking substrate. The product should then be unrolled on to the deck whilst simultaneously pulling off the siliconised film.

At all times, we recommend that this product is installed in accordance with the NFRC’s Safe2Torch guidelines.At installation temperatures below 10°C the laps should be pre-heated using a hot air welding gun.