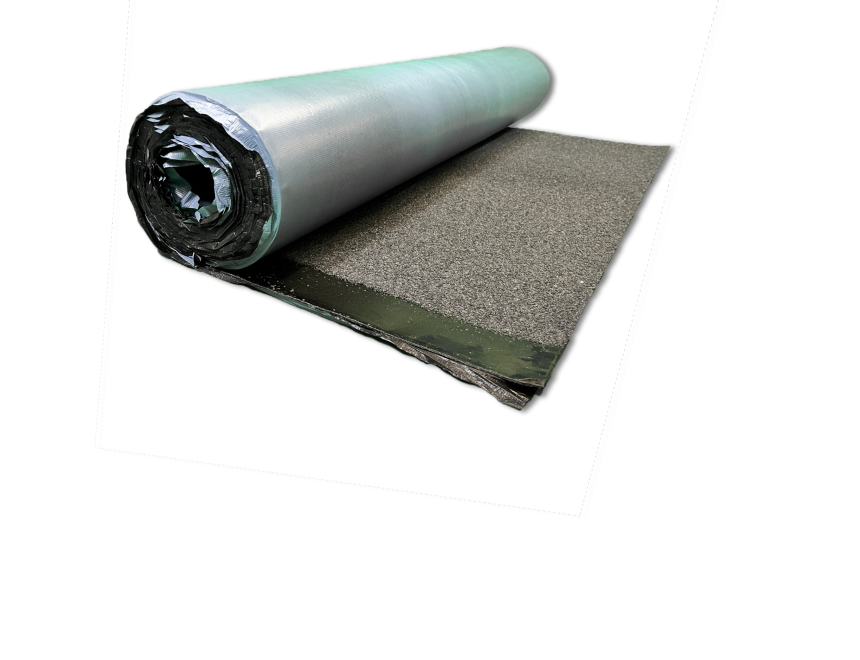

STRATAPRO M SA

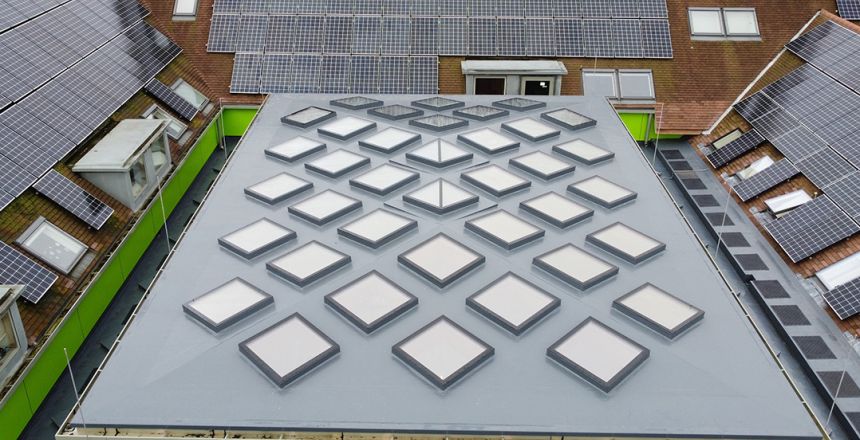

Self-Adhesive Bituminous Waterproofing System

The STRATAPRO M SA range has been developed to provide a traditional two-layer felt system without the associated risks from torching. The system offers outstanding membrane technology, combining SBS and APP bitumen to provide a strong and flexible waterproofing system.

ICB (Waterproofing)Ltd commissioned independent testing of the STRATAPRO SA system for reaction to fire and resistance to wind loading. The system, using a build-up of STRATAPRO M SA, STRATABASE SA and PIR insulation has been tested to both BS476:3 and DD ENV 1187 and holds EXT.F.AB and BROOF(t4) respectively.

The system was also subjected to dynamic wind uplift testing and can withstand wind uplift forces of up to 5 kPa*.

Usage

- Areas where hot works are not permitted

Product Details Back to top

Technical Data

| Reinforcement | Composite Three-Layer Non-Woven Spunbound and fibreglass | ||

|---|---|---|---|

| Thickness | EN 1849-1 | ±0,2 | 3mm |

| Weight Mineral | EN 1849-1 | ±15% | 4.5 kg / m2 |

| Roll Size | EN 1849-1 | ≥ | 1x8m |

| Watertight After Aging |

EN 1928-B EN 1926-1928 |

≥ | 60 kPa |

| Peel Resistance | EN 12316-1 | -20N | 100 N/50 mm |

| Shear Resistance L/T | EN 12317-1 | -20% | 6550/550 |

| Maximum Tensile Force L/T | EN 12311-1 | -20% | 750/650 |

| Elongation L/T | EN 12311-1 | -15% V.A. | 50/50% |

| Resistance to impact | EN 12691-A | 1 250mm | |

| Resistance to static loading | EN 12730-A | 20kg | |

| Resistance to tearing (nail shank) L/T | EN 12310-1 | -30% | 250/250 N |

| Flexibility to low temp. after aging |

EN 1109 EN 1296-1109 |

≤ +15°C |

-15 °C/ -25 °C -20 °C |

| Flow resistance at high temperature after ageing |

EN 1110 EN 1296-1110 |

≥ -10°C |

100 °C 90 °C |

| Reaction to fire Euroclass External Fire Performance | EN 13501-1 |

E Broof (t4) / EXT.F.AB |

|

| UV Ageing | EN 01297 | Test Passed | |

| Thermal Conductivity | 0.2 W/mK | ||

| Heat Capacity | 5.40 KJ/K-m2 | ||

| Dimensional Stability | EN 1107-1 | ≤ | -0.20/+0.10% |

Applications Back to top

Primer will need to be applied in all instances. Store the rolls in a cool dry place until you are ready to lay the membrane; rolls should remain unopened until immediately before laying. Attention should also be paid to the weather conditions on the day of installation; low temperatures reduce the adhesion properties of the membrane, while high temperatures soften the membrane and adhesive, making it more viscous thus slowing down application. In hot conditions it is important to remove the protective film only when you are sure that the sheets are properly aligned. Once they are bonded it is difficult to separate and realign them.

In cold or foggy weather conditions, moisture can condensate on the roof deck and on the membrane, inhibiting adhesion; in temperatures below +5°C laying should be suspended.

For slopes over 15° or in exposed locations, mechanical fastenings may be required. Please seek assistance from ICB (Waterproofing) LTD.