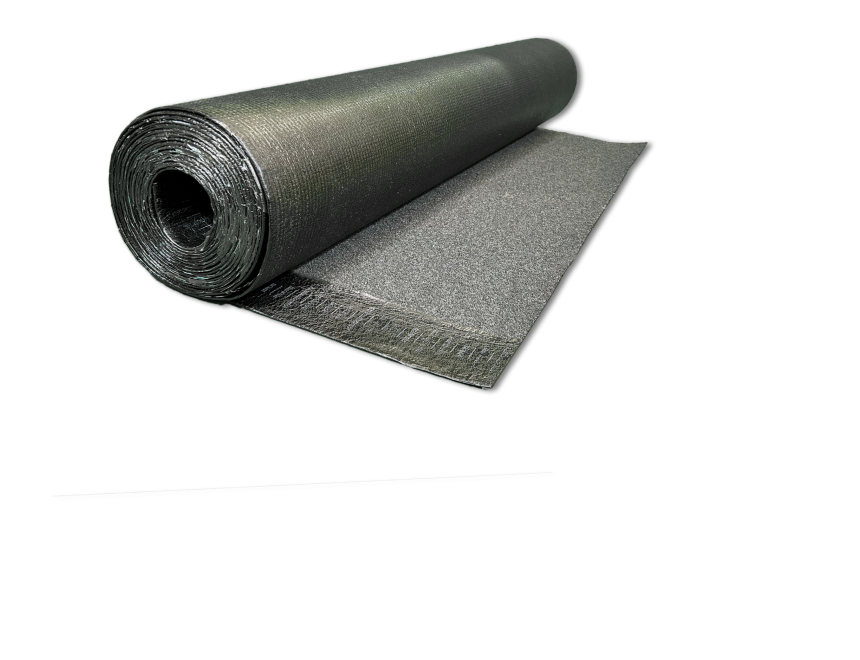

STRATAPRO & STRATA PRO M

Multi-Layer Composite Bitumen Waterproofing Membranes

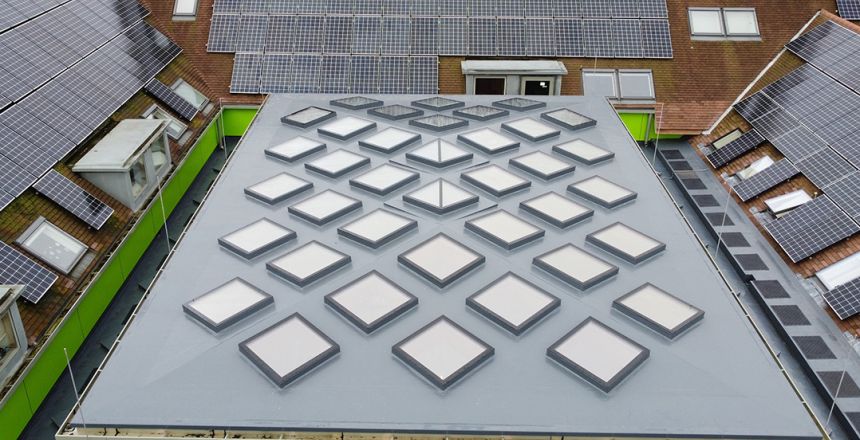

STRATAPRO and STRATAPRO M are multi-layer composite bitumen waterproofing membranes. The underside of the membranes are made of SBS modified bitumen, while the upper layer is made of APP-modified bitumen. The SBS on the lower face offers high level of flexibility, and boast elongation of up to 2000%, it will remain flexible in temperatures as low as –25°C, and has a high resistance to thermo-oxidative ageing. The upper layer consists of an elastoplastomeric mix of distilled bitumen, atactic and isotactic polypropylene and UV resistant polyolefin elastomers, supplemented with thermal shock stabilisers STRATAPRO provides a smooth finished surface whilst STRATA PRO M provides a mineral slate finish.

STRATAPRO and STRATAPRO M have a composite prefabricated threelayer reinforcement system. A fiber glass mat is compressed between two layers of non-woven polyester fabric, this reinforcement limits the movements of the membrane both at high and low temperatures providing stability to the membranes. STRATAPRO and STRATAPRO M are suitable for both torched application and mechanical fixing, the fibres within the membrane are impregnated and coated with an elastomeric mix using an exclusive procedure which guarantees absolute waterproofing, high resistance to tearing and impact, and excellent elasticity even at low temperatures.

Advantages

- Can be applied in a single layer or as a finishing layer in a multi-layer system

- High mechanical strength, flexibility, thermal stability and durability, suitable for both hot and cold climates

- Strong welds obtained on the smooth upper face, both for the side and end joints, guarantees perfect bonding even on flat areas and in the presence of ponding

- Elastomeric membranes with excellent fatigue strength of these , even when they are fully bonded,allowing resistance to dimensional variations and active cracks which appear on cement surfaces.

Usage

- Roofs subject to considerable dimensional variations

- Hot and cold climates

- Flat areas

- Cement surfaces

Product Details Back to top

Technical Data

| Reinforcement | Composite Three-Layer Non-Woven Spunbound and fibreglass | Composite Three-Layer Non-Woven Spunbound and fibreglass | ||

|---|---|---|---|---|

| Thickness | EN 1849-1 | ±0,2 | 3mm | |

| Weight Mineral | EN 1849-1 | ±15% | 4.5 kg / m2 | |

| Roll Size | EN 1849-1 | ≥ | 1x8m | |

| Watertight After Aging |

EN 1928-B EN 1926-1928 |

≥ | 60 kPa | |

| Peel Resistance | EN 12316-1 | -20N | 100 N/50 mm | |

| Shear Resistance L/T | EN 12317-1 | -20% | 6550/550 | |

| Maximum Tensile Force L/T | EN 12311-1 | -20% | 750/650 | |

| Elongation L/T | EN 12311-1 | -15% V.A. | 50/50% | |

| Resistance to impact | EN 12691-A | 1 250mm | ||

| Resistance to static loading | EN 12730-A | 20kg | ||

| Resistance to tearing (nail shank) L/T | EN 12310-1 | -30% | 250/250 N | |

| Flexibility to low temp. after aging |

EN 1109 EN 1296-1109 |

≤ +15°C |

-15 °C/ -25 °C -20 °C |

|

| Flow resistance at high temperature after ageing |

EN 1110 EN 1296-1110 |

≥ -10°C |

100 °C 90 °C |

|

| Reaction to fire Euroclass External Fire Performance | EN 13501-1 |

E Broof (t4) / EXT.F.AB |

||

| UV Ageing | EN 01297 | Test Passed | ||

| Thermal Conductivity | 0.2 W/mK | |||

| Heat Capacity | 5.40 KJ/K-m2 | |||

| Dimensional Stability | EN 1107-1 | ≤ | -0.20/+0.10% |