FLEET LD Coating

Hard Wearing Layer

The Fleet LD Coating is used as a wearing layer for Fleet systems. Offering excellent abrasion-resistance and non-skid properties, this product was developed specifically as heavy-duty surfacing and can be applied to asphalt substrates without a primer. The surface can be of any colour and this coating can even be used to create patterns or car park markings and guidance.

Advantages

- Maximum abrasion resistance

- Maximum anti-skid properties

- Variable roughness

- Permanently weather-resistant (UV-, hydrolysis- and alkali-resistant)

- Any RAL colour

- Pattern and colour design possible

- Easy and fast application

- Fast-curing

- Solvent-free

Usage

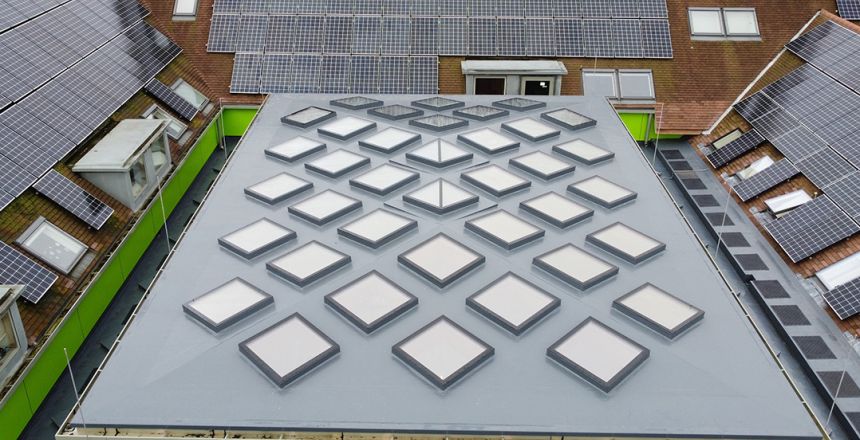

- Parking areas

- Garages and courtyards

- Hotel driveways and terraces

- Footpaths and cycle paths, footbridges

- Schoolyards

- Town and market squares

- Outdoor cafés and beer gardens

Product Details Back to top

Product Specification

| Packaging |

Summer: 15.00 kg Fleet LD Coating |

Winter: 15.00 kg Fleet LD Coating |

|---|---|---|

| Colours |

Fleet LD Coating is available in the following standard colours: RAL 7030 Stone grey |

Technical Data

| Density |

approx. 2.2 kg/m² |

|---|

Applications Back to top

For mixing the product

- Twin-paddle stirrer

For applying the product

- Aluminium blade approx. 60 cm

- Smoothing trowel

Mixing

First stir the tub contents thoroughly. Then add the catalyst while stirring at the slow-speed setting and mix for 2 minutes. Make sure that the product on the base and sides of the container is mixed in. Ideally the roller-applied coating should therefore be re-potted once before stirring again. At product temperatures < 10 °C the product should be stirred for 4 minutes, as the catalyst will take longer to dissolve.

Application

Use a smoothing trowel to spread the material evenly and smooth it over, using the particle size as a guide to layer thickness. The advantage of using the aluminium blade is that this can minimise the otherwise normal trowel marks to create a smooth and even appearance. To achieve the desired texture, go over the area with a sheepskin roller.