FLEET Coat 30

Main area waterproofing

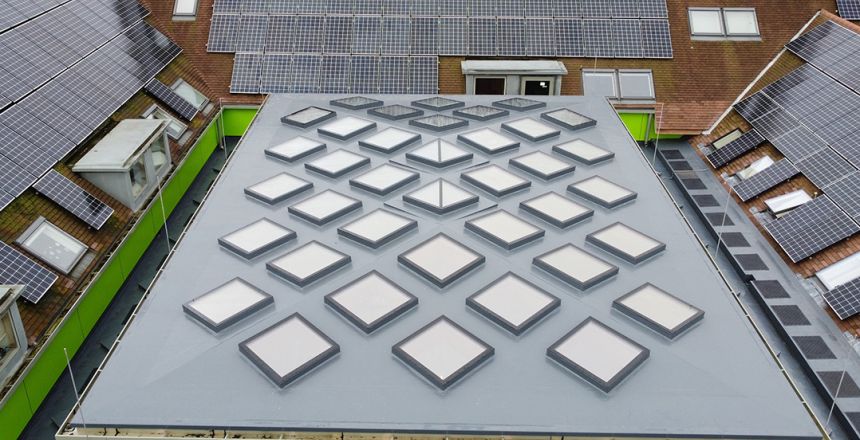

Fleet Coat 30 products are high-grade, PMMA-based waterproofing resins with low-temperature flexibility and are used to create durable and reliable roof waterproofing membranes and to waterproof joints on water impermeable concrete with fleece reinforcement. Its liquid application allows seamless waterproofing systems to be applied to large areas, and even the most complex roof penetrations and details to be securely incorporated.

BBA Accredited

Advantages

- Highly flexible and crack-bridging even at extreme sub-zero temperatures

- Permanently weather-resistant (UV-, hydrolysis- and alkali-resistant)

- Fully bonded to the substrate, therefore no flow paths for water under the membrane

- Easy and fast application

- The most complex roof penetrations can be securely incorporated in the seamless waterproofing system

- Fast-curing

- Can be applied to almost all substrates, including variable substrates (when combined with Fleet Primers)

- Solvent-free

- Test certificates and technical approvals (ETA, AbP) for the areas of roof waterproofing and the waterproofing of joints on water-impermeable concrete units

Usage

- Large areas and details

- Water-impermeable concrete joints

- Horizontal areas

- For utilised roof areas under other Fleet products

- As a waterproofing membrane underneath surfacing provided by others

Product Details Back to top

Product Specification

| Packaging |

|---|

|

Summer: The 10kg containers should be used with catalyst. |

Winter: 10.00 kg0.60 kg 10.60 kg Catalyst (6 x 0.1 kg)

|

Applications Back to top

For mixing the product

- Twin-paddle stirrer

For applying the product

- Sheepskin roller

- Brush (only for areas not accessible with a roller)

Apply the waterproofing resin to the cured Fleet Primer or suitably prepared substrate

Mixing

- First stir the tub contents thoroughly.

- Then add the catalyst while stirring the resin at the slow-speed setting and mix for 2 minutes. Make sure that the product on the base and sides of the container is mixed in.

- At product temperatures <10 °C the product should be stirred for 5 minutes, as the catalyst will take longer to dissolve.

Use Fleet Coat 30 for waterproofing horizontal areas.